Some problems existing in the waste gas treatment of the pharmaceutical and chemical industry and the specific method to solve the waste gas treatment problem in the industry, of course, the industry is mainly the waste gas treatment problem of solvents:

Problems existing in the treatment of solvent waste gas in pharmaceutical and chemical waste gas treatment

After the control and treatment of pharmaceutical and chemical waste gas by relevant departments, it has been significantly improved, but it has not been well improved. There are still obvious solvent waste gas treatment problems in the pharmaceutical and chemical industry. Some enterprises with serious air pollution from pharmaceutical and chemical waste gas have been closed down after the treatment is ineffective to improve the air environment around pharmaceutical and chemical production enterprises. The pollution index in the air has dropped significantly. Radical exhaust emissions are treated. In order to achieve a good exhaust gas emission effect and reduce the pollution of the surrounding environment, after the long-term control and treatment of pharmaceutical and chemical solvents, the exhaust gas emission index has been reduced.

Pharmaceutical and chemical waste gas control effect

For most pharmaceutical and chemical enterprises, it is necessary to establish a solvent waste gas treatment mechanism with high safety, carry out clean pharmaceutical and chemical production, improve solvent waste gas emissions, and adopt a reuse plan for solvent waste gas, so as to reduce the pollution of solvent waste gas and reduce the pollution of solvent waste gas. It can improve the utilization value of the solvent, thereby reducing the pollution of the surrounding environment caused by the exhaust gas emission of medicine and chemical industry. For pharmaceutical and chemical waste gas treatment, solvent waste gas discharge treatment should be improved from the root cause, effectively control the centralized treatment and discharge of solvent waste gas, reduce the multi-faceted environmental pollution caused by multi-point discharge, and take fundamental measures to improve the problems existing in solvent waste gas discharge and effectively control The waste gas formed by the pharmaceutical and chemical industry is cleaned and treated to effectively reduce the pollution to the surrounding environment, and centralized treatment and discharge are carried out.

Solvent waste gas treatment results

For the solvent waste gas produced in the pharmaceutical and chemical production, there are many problems in the waste gas treatment, and the cleaning treatment technology for the solvent waste gas has not been well perfected. The author believes that the solvent waste gas generated by the pharmaceutical and chemical industry has a serious pollution effect. At present, cooling, cleaning and other treatment methods are generally used for solvent waste gas. However, the effect of solvent waste gas treatment is not very satisfactory. This has always been an important problem that has plagued the development of the pharmaceutical and chemical industry and exhaust gas emissions. The problem of exhaust emission should be solved more vigorously, so as to improve the exhaust emission and the quality of the surrounding environment.

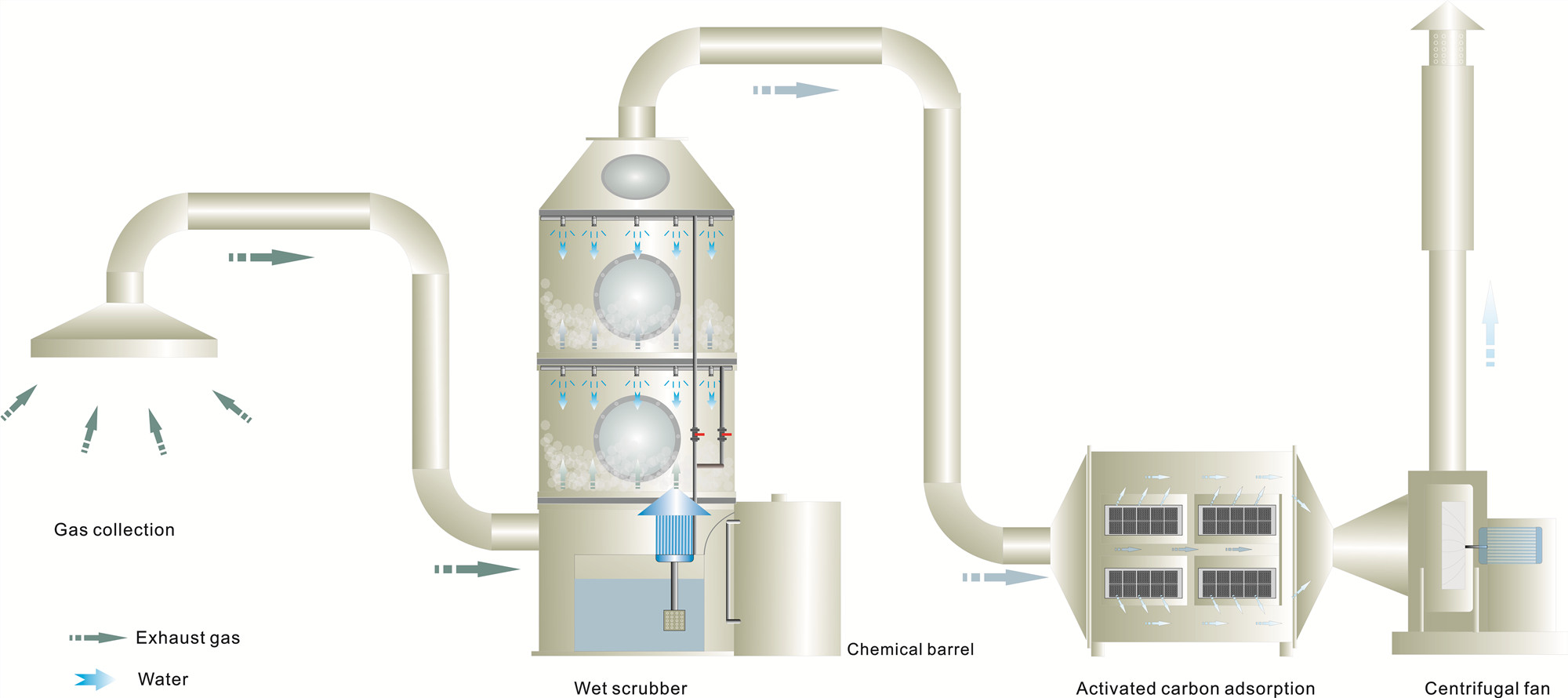

processing unit

1. Pretreatment: Collect exhaust gas centrally. Special treatment is required for high temperature exhaust gas or oil fume exhaust gas, and equipment such as condensing equipment or oil fume purifier is added to pretreat exhaust gas.

2. Wet scrubber system: the pretreated exhaust gas will enter through the bottom end of the wet scrubber, and enter the spray system combined with the multi-layer spray structure and the multi-faceted ball packing to further remove the acid and alkali gases in the exhaust gas. The neutralization reaction can effectively purify the pollutants in the exhaust gas, and the purification efficiency can reach more than 85%. The purification efficiency can be increased to more than 95% through the combination of multiple exhaust gas scrubbers.

3. Activated carbon adsorption: Activated carbon adsorption equipment can effectively filter organic matter in exhaust gas, and can well filter irritating odor in exhaust gas. Activated carbon adsorption equipment is often used to purify air and filter odors.

4. Centrifugal blower: The centrifugal blower is the main power of the scrubber system, and the collection and discharge of exhaust gas require the high-speed operation of the centrifugal blower. Because there are a lot of corrosive substances in the exhaust gas, the blower must choose an anti-corrosion blower.

Solvent organic waste gas treatment finished product diagram:

The above set of solutions is an organic waste gas treatment solution tailored for the pharmaceutical company.