What is a lifting sling, and how are they used?

Lifting slings usually double girder eot crane, rope, or webbing used in alliance with a crane for lifting purposes. It facilitates moving heavy materials from one place to another while also keeping the balance of the load.

Workers practising rigging must exercise extreme cautiousness when involved in lifting processes that include using slings. Operators should receive training before participating in the lifting procedures, and you must monitor the splints frequently to avoid hazards.

Types of Slings:

Here is a brief guide to the main types of slings you can choose from as per your need.

Alloy Chain Slings: Chain slings lift very hefty and enormous loads daily. However, when it comes to durability and endurance, they are the perfect fit. They can withstand high temperatures and adversities almost up to 1000°F. Once damaged, the chains are repairable and ready for use after the load testing. They are not affected by grease or oil and are tolerant to corrosion and UV rays.

Wire Rope Slings: You can configure the wire rope slings with single-leg designs. It is an ideal lifting device because of the flexibility it offers. Its cost is lower as compared to alloy chains and is also lighter design-wise. These slings have common use in the manufacturing industries as a lifting mechanism.

Synthetic Web Slings: Synthetic web slings are preferable for lifting delicate and high-polished loads because it protects them from scratches, unlike other slings. Usually made from woven polyester or nylon, they make a good choice as it is cost-effective. Despite being made from soft materials, they are capable of lifting expensive and heavy loads. However, you can't use it in conditions exceeding 194°F.

Guide to select the ideal sling:

While choosing a sling, there are a few things to keep in mind. Here, is everything you must know before selecting the ideal sling:-

The weight of the load:

It is crucial to determine the weight of the load before lifting it. It helps to ensure the safety of the workers present at the site from any possible mishaps. One of the ways to measure the weight of the load is to manually calculate it.

Another way can be following a load chart. A load chart helps in estimating the need for extensive calculations. It is also important to recalculate this since the lift range can keep varying.

The Working Load Limit of the sling in use:

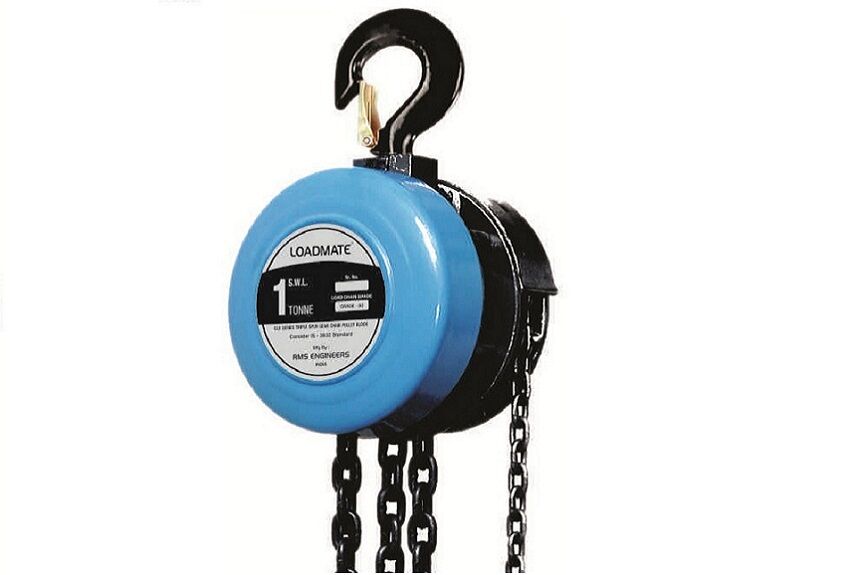

While choosing the ideal sling, it is important to keep its Working Load Limit (WLL) in consideration. It is extremely vital because the sling in use should handle the size and weight of the load.

For example, chain slings help lift bulky loads as compared to synthetic slings. However, if you end up opting for the wrong sling, it would have a risky possibility of the load getting dropped.

For more information:- eot crane company in india

The Environmental Factors:

Environmental factors play a major role in choosing the right sling. You need to be conscious about the details like temperature and the presence of corrosive substances.

You should take indoor working conditions into account. For example, Chain slings can endure extreme temperatures up to 1000°F. On the other hand, wire rope slings can only withstand temperatures up to 400°F. Moreover, synthetic slings are more likely to be damaged easily compared to metal mesh slings in case of corrosive substances.

The properties and features of the varied slings:

Each sling has different characteristics. Therefore, it is necessary to keep those in mind to be able to recognise the perfect fit.

Every sling is different and uses discrete materials. Keeping the material of the sling in mind assists in observing what goes best as per your requirement. The fragility of the materials depicts the distinct use of each. For example, chain slings are compatible with repetitive use because of their longevity. However, synthetic web slings are used for the flexibility they provide.

Working Load Limit:

The working load limit (WLL) or previously known as safe working load (SWL) indicates the ultimate working load designated by the manufacturer. Exceeding the maximum limit can be threatening to the worker's safety. Be mindful of the working load limit always being 1/3 of the breaking limit.

Some factors determining workload limit are:-

Design Factor: For example, the design factor of chain slings is 4:1 whereas for wire rope sling it is 5:1.

Loading Angle: Sling to load angle can be described as the angle between the sling leg and the horizontal surface. Therefore, as the sling to load angle decreases, so does the given capacity of a sling.

Endurance of Material: Construction of the sling, their material and strength are factors affecting workload limit (WLL).

So, these are the important points and factors that you have to perceive. It will give you an idea of the functionality of the slings. In the future, if you want to establish a business that involves slings, these pieces of information will help you.